Kobold Press CEO and Kobold-in-Chief, Wolfgang Baur, is here to give you some insight on the state of the industry!

As promised last time when we discussed small print runs, it is now time to talk about “real printers,” meaning an offset press with lithography. This involves a very different process than print-on-demand runs.

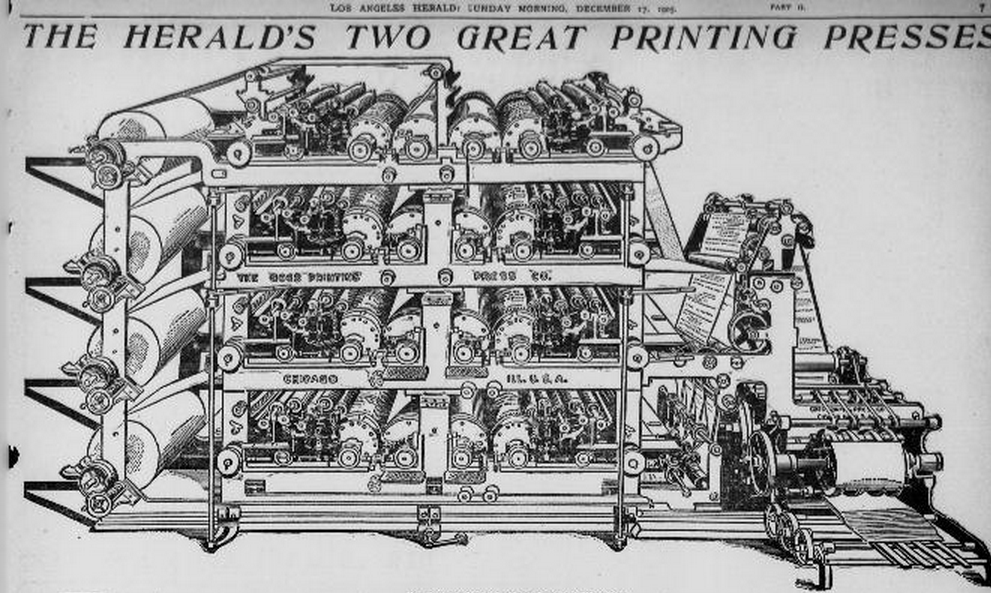

The manufacturing is what people think of as traditional printing, which consists of someone creating etched metal plates, running giant rolls of paper though the machine using a sheet-fed printer mechanism, and then followed by folding, gathering, trimming, and binding (often sewn bindings and often in hardcovers).

The technique is more modern than the single-sheet presses of Gutenberg’s time! (Here’s a video that goes into a little more detail about modern offset printing.) Offset really started with printing on tin in the United Kingdom around 1875, then on paper in the United States starting in 1904.

The technology is just as complex as the digital presses I discussed last time. It assumes a higher level of familiarity with press requirements, and it’s more demanding on the production team to turn over files that work.

High-Speed Press

So why go to all this trouble? The reason, as is often the case with manufacturing, is money. Unlike print on demand, once you create the metal plates to print a book from, you can print all the livelong day, book after book after book. As many as you can sell. Each copy you print costs less, because you are amortizing the cost of the plates and setup work over the number of books you are printing.

As an example, a $20,000 setup fee divided by 500 books is a cost per book (a.k.a. unit cost) of $40 per book. In the RPG world, it’s hard to make money selling that.

However, that same $20,000 setup fee divided by 5,000 books is a unit cost around $4 per book. And if you are the world’s biggest RPG and your print runs start at 50,000 copies, you’re paying perhaps 40 cents per book. (It’s actually more because your have to buy paper too, but the creation of plates and size of the run drives the unit costs.)

Setting a Print Run

So how big a print run should you do with an offset press? 1,000 books is roughly the minimum, because any less than that and your cost per book is generally lower with a print-on-demand approach.

The natural temptation here is to look at the massive cost savings you get by printing “just a few more” copies. Printers will quote you a price for 1,000 copies, and also 1,500 copies and even 2,000 copies. Then you’ll see that printing 2,000 copies is a MUCH BETTER DEAL per book than printing 1,000. Maybe the 1,000 books cost $15 each, and the 2,000 books cost just $9 each. If you are paying $15,000 for 1,000 books, why NOT pay $18,000 for literally twice as many!?

By Grabthar’s Hammer, by the Sons of Warvan, the savings!

Do not follow that dark logic. This is a siren song of disaster. It is the road to having a warehouse full of unsalable books. Unsalable books that cost “just a little more.”

Inventory Is Death

Guess what? Most warehouses, even in quite distant corners of the world, charge you for everything they store. They charge you whether the book is selling great or not selling at all. They charge winter and summer. Inventory costs every day, all the time. Storing 1,000 extra books maybe costs you $50 or $75 more in storage fees per month. Call it $1,000 per year in storage as a nice, round number. If those books don’t sell, maybe you pay for warehousing for 3 years and then have to pulp them anyway.

You might think you’ll save money by storing them in your garage or your uncle’s barn or something, but you’re inviting mystery trouble that way. I can’t tell you ahead of time what that trouble will be, but it’ll be the kind of trouble you’d probably rather pay $50 a month to avoid.

Don’t overprint. Just don’t do it. Don’t give in to “but it’s just a little more money! We’ll have more to sell!” Because while you might sell more, you definitely will pay more to store them. Month after month, those fees add up.

Print what you can sell in a year or two. No more, unless your uncle’s barn definitely won’t make your books smell like mildew and cows.

Printers are Ubiquitous. Quality Varies.

Offset printers exist in every country with a half-decent industrial base, and like many industries, they specialize. Some do mostly novels or yearbooks or board games or card games, or art books or schoolbooks. The cost of a good 4-color press can run from tens of thousands of dollars for a small, used press to millions of dollars for the big, high-speed behemoths. Then the quality of paper, ink, and color varies depending on the materials and the team setting up the job.

Every printer wants their press running for as many hours as they can make it run, to maximize their earnings. Some take jobs they aren’t ready for, or move you to the back of the line, or take forever because better-paying work is available from a bigger customer.

Choosing a print house is starting a relationship. Don’t be late, don’t constantly revisit the quote, don’t change your mind about the quantity every week (and I say this as a publisher who has done all those things). The print run is a moving target, but try to hold up your end of things so the press doesn’t think you are a flighty, disorganized creative-but-difficult mess.

Printers By Name

The decision about where to print a big run like this is a major one. You can ask a print broker to help you. You can try to time tariffs and manage shipping costs. But ultimately what you want is someone who communicates costs clearly and fairly, handles corrections and shipping to the degree you need that help, and makes it at least possible that your print-ready files match their standards and templates. With offset printing, you spend more time matching color profiles and selecting materials than you do with a digital press, because there are more options. It’s a learning curve, so be ready to get schooled.

Here’s some names to get you started, some of which Kobold Press has worked with. I’m sure there are many others. The main thing is to get a few quotes for the same paper, same page count, same quantity, same shipping—and then make a decision.

Ask about schedules. Ask about packaging and customs handling. Every printer want your business, but the bigger ones are looking for bigger jobs, so finding a printer who’s a right fit for your job is useful.

Some places simply hustle harder to get you a quality RPG hardcover. It’s worth asking them who their other customers are in the field.

Canada

China and Hong Kong

Hsing Cheng Printing Industry HK Co.

US

This is a lot of options. I can’t say what’s right for your RPG, softcover or hardcover, big or small. But if your audience is big enough, it’s worth finding a printer who can provide great quality at a great price. Dig around. Ask for quotes. And good luck!

It’s the last day for our Player’s Guide 2 Kickstarter Campaign! Back it now before it’s too late!

Read more at this site